The pharmaceutical industry is one of the only markets in the United States that can be expected to remain relatively steady. This is not only due to its size, but its necessity.

Americans are reliant upon the pharmaceutical industry for their medications, and even during the COVID-19 pandemic, these medications must remain readily available for consumers. With that being said, the pharmaceutical industry cannot function properly without laboratories. Pharmaceutical labs are responsible for the rapid and efficient manufacturing of medications and other pharmaceutical products. However, more important than the speed of production is the quality and safety of production.

In the past, issues have occurred when laboratories did not follow proper safety practices. One particularly alarming case occurred in 2012. A fungal meningitis outbreak was discovered in the U.S. and was eventually traced to a Northeastern pharmacy. Before the source was discovered and the drug recalled, there had already been 48 deaths. The true reason why the outbreak and therefore the deaths occurred is that there were shortcuts made during production. Essentially, there were failures in cleaning and quality control. This is why Good Manufacturing Practices, or GMP, must now be followed in order to ensure that the products released are as clean and safe as possible. GMP standards cover a number of different processes and aspects of laboratory manufacturing procedures. There are five key elements to GMP quality assurance, in particular, sometimes referred to as the "five P's'" of GMP. They will be further explored below.

1. Products And Primary Materials

Perhaps the most important element of pharmaceutical production is that of products and primary materials. The product is the final result, which will be sold to consumers, whereas primary materials are the raw ingredients used to make the product. This is where issues can often begin. If primary materials are not properly assessed before production, a flawed product can be made. However, that product then must be reassessed before it is put on the market. This is why GMP standards demand a master formula be followed for final products, with no deviation, and that quality is assured through constant testing and comparisons.

2. Premises And Equipment

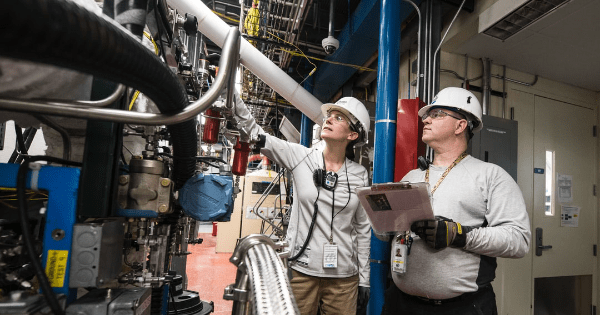

Laboratories must maintain uniform premises and equipment. Equipment, in particular, can experience a good deal of variation. For example, looking at fume hoods, common pieces of equipment in pharmaceutical labs, laboratories can easily keep overused fume hoods in an effort to cut costs and avoid the buying of new equipment. However, investing in new fume hoods ensures that the best practices are being followed and that there is less of a risk of equipment failure. This would also apply to how the fume hoods are being used and maintained, along with the surrounding premises. These same principles can be applied to any types of equipment, as well as laboratory surroundings themselves.

3. People

Practices can never be properly implemented if the people working with a lab are not properly trained. While it does take time and investment to train employees in GMP quality control standards, this is crucial to the implementation of procedures. Furthermore, the training methods with which employees are educated must be assessed and reassessed on a regular basis, to ensure that they are up to date.

4. Procedures

Of course, the procedures themselves must also be scrutinized. These procedures must be constantly updated, as technology is updated and more is learned about pharmaceutical processes. All procedures must also be well-documented. This means that if there is an issue during the manufacturing process, it can be easily traced back to the source.

5. Processes

The processes of GMP essentially refer to the documentation that can be used to prove that procedures will be followed. Auditors regularly check laboratories, to ensure that they are following GMP procedures, GMP storage conditions, and more. By keeping documentation regarding processes, laboratories will be able to better ensure that they are acting properly.

Following these procedures allows laboratories to function independently, while still complying with standards that will ensure the safety of consumers, as well as the satisfaction of pharmaceutical companies. When the manufacturing of such delicate products is involved, standards must be followed.