Developing and manufacturing a radiolabeled compound is a delicate science. The unqualified truth is that those in the chemistry field consider radiolabeling as an art, as the process expresses important concepts and creates with great skill. Radiolabeling requires in-depth expertise, knowledge, practice, and precision. Why? Extensive studies evaluate the function and value of the radiolabeled compound, and any mistakes will slow down the development timeline.

For this reason, experience with the complex process is critical to ensure safety and efficiency during each step. The possibilities of radiochemical projects can be endless, based on the targeted result and chosen synthesis route. Expert radiochemists must carefully determine the best activity route depending on the isotope species and the specifics of a project. The correct identification of a labeling position—alongside analytic checks for chemical purity—helps assure consistency and quality.

The completion of radiolabeled compound synthesis or analysis should be compliant with current good practices and quality control standards. Besides this quality assurance, all radiochemical materials require proper handling and storage due to their inherent instability. Let’s examine closely what this all entails. Here’s a look at how to properly store your radiolabeled compounds.

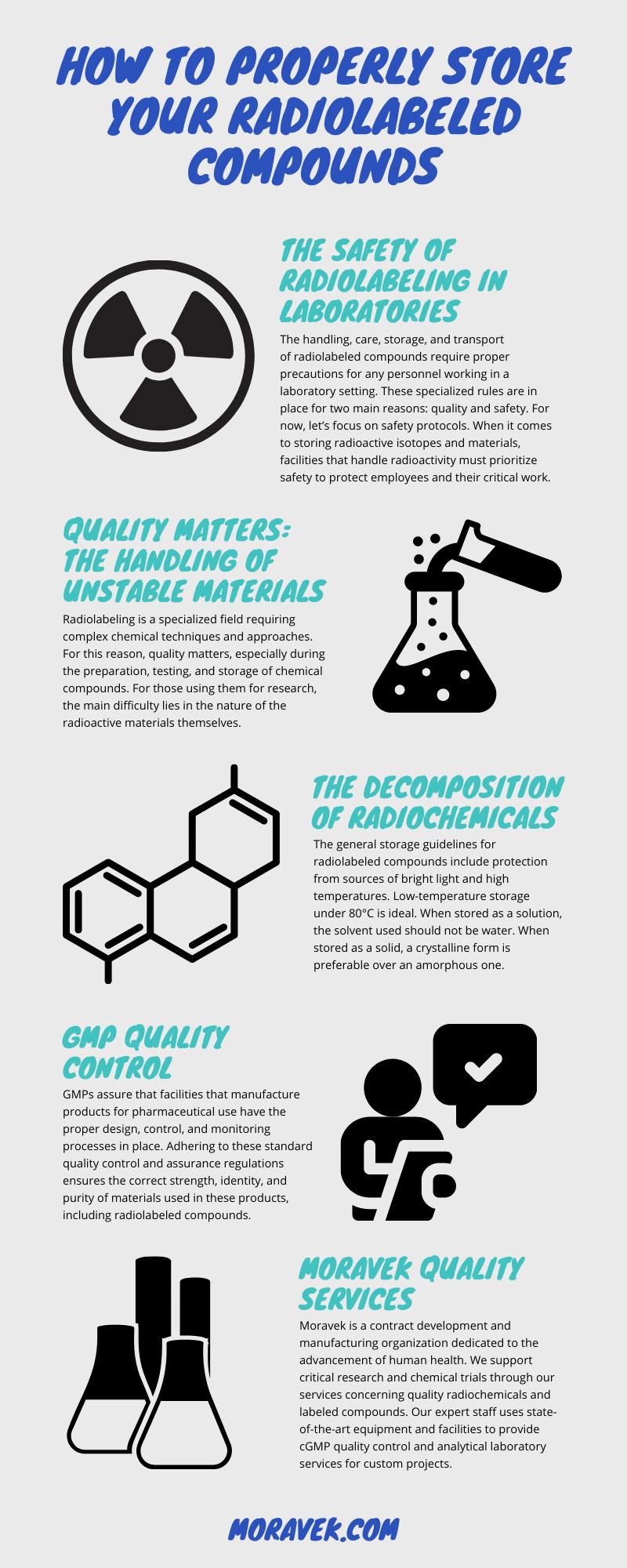

The Safety of Radiolabeling in Laboratories

The handling, care, storage, and transport of radiolabeled compounds require proper precautions for any personnel working in a laboratory setting. These specialized rules are in place for two main reasons: quality and safety. For now, let’s focus on safety protocols. When it comes to storing radioactive isotopes and materials, facilities that handle radioactivity must prioritize safety to protect employees and their critical work.

Interlock systems, stability chambers, surveillance equipment, ventilation methods, active radiation monitoring, and proper personal protective equipment are all integral for laboratory projects using radiolabeled compounds. For protective purposes, no personnel should store food, beverages, medicines, or paraphernalia in freezers, refrigerators, cold rooms, or areas where facilities use or store radioactive materials.

Quality Matters: The Handling of Unstable Materials

The exact amount of chemicals and type of chemicals used varies across laboratories. This depends on the lab's targeted specialties, such as analysis services, contract research, compound synthesis, compound production, and more. The general rules for handling chemicals apply to laboratory work involving radiolabeled compounds for clinical research or pharmaceutical development.

Radiolabeling is a specialized field requiring complex chemical techniques and approaches. For this reason, quality matters, especially during the preparation, testing, and storage of chemical compounds. For those using them for research, the main difficulty lies in the nature of the radioactive materials themselves.

Radioactive chemical atoms organically decay through a process known as radioactive decay. This natural process occurs when unstable radioactive substances spontaneously emit particles to reach a stable state. The specific decay rate—measured in terms of a half-life—remains constant over a longer period of time; yet, radiochemists cannot predict precisely when the atom will begin to decay. Ergo, radioactive isotopes as unstable atoms need special care and attention in laboratory settings.

The Decomposition of Radiochemicals

By their very definition, radiolabeled compounds emit diverse levels of radiation. As mentioned above, this process can more greatly accelerate their rate of decay. The user of a radiolabeled compound should always keep the compound's shelf life in mind. Otherwise, they cannot use the labeled compound in confidence for the purposes of their project.

Remember, chemical compounds naturally decompose during their time in storage. The specific rate of decomposition depends on the compound in question. Compared to unlabeled compounds, compounds labeled with radioisotopes—radiolabeled compounds—typically decay much faster. The reason is due to radiolytic decomposition. Radiation has the ability to make unique changes to these active chemical substances. Unless testing reveals this is not a top concern, users must assume that radiochemicals may produce unpredictable activity in various storage conditions.

The general storage guidelines for radiolabeled compounds include protection from sources of bright light and high temperatures. Low-temperature storage under 80°C is ideal. When stored as a solution, the solvent used should not be water. When stored as a solid, a crystalline form is preferable over an amorphous one.

GMP Quality Control

Curious about how to properly store your radiolabeled compounds for testing or analysis? Continue to keep safety and quality in mind. The best practice is using storage methods that meet GMP standards. cGMP refers to current good manufacturing procedures regulated by the US Federal Drug Administration.

GMPs assure that facilities that manufacture products for pharmaceutical use have the proper design, control, and monitoring processes in place. Adhering to these standard quality control and assurance regulations ensures the correct strength, identity, and purity of materials used in these products, including radiolabeled compounds.

Implementing these GMP practices successfully depends on appropriate environmental maintenance and human compliance. Facilities must keep laboratories sterile or utilize a clean room for scientific work. The awareness of air quality control is essential to prevent contaminating or compromising the purity of radiolabeled compounds. Both environmental setup and continuous monitoring are vital for quality control.

Suitable Storage Conditions

Radiolabeled compounds are stored best in chambers in experienced stability testing, monitoring, and storage facilities. The areas that these chambers are in should be secure with locking systems and consistent, validated monitoring. This type of comprehensive storage is the only method to ensure the proper management and completion of specific studies.

For those seeking secure storage facilities to meet the customized requirements of your radiolabeled compound project, look for contract organizations capable of providing proper temperature, air quality, and humidity conditions. Their qualified radiochemical housing chambers should be adequately controlled, monitored, and managed.

Also, check and make sure that personnel can safely perform reanalysis or repurification before transport occurs. Radiolabeled compounds must be ready for use after their time spent in storage. This method ensures you can meet the timelines of your specific study, trial, or project.

Moravek Quality Services

Moravek is a contract development and manufacturing organization dedicated to the advancement of human health. We support critical research and chemical trials through our services concerning quality radiochemicals and labeled compounds. Our expert staff uses state-of-the-art equipment and facilities to provide cGMP quality control and analytical laboratory services for custom projects.

We support our client’s needs with radiochemical stability studies, method feasibility, development, and transfer, alongside appropriate storage conditions. The team in our dedicated QC laboratory is knowledgeable on the best handling and storing methods of radioactive materials. With our FDA-compliant monitoring system, we safely store radiolabeled compounds facing decomposition processes. Contact us to learn more about our facility’s sophisticated storage, analysis processes, and stability solutions.